In

the previous section we saw the analysis of sections by the working

stress method. There we saw that after the end of phase 2, the

stresses are higher and 'non-linear'. We discussed it based on fig.2.13 Here we are going to discuss the analysis at ultimate state. That

is., the state when the failure of a section is impending. To know

the behaviour of the section at the point of impending failure, we

must load the section up to that point, and then analyse the results.

As the materials reach the state of impending failure, the stresses

will be very high. So the stress distribution will be very much

non-linear. In other words, the stress distribution graphs will be

curves.

We

require such a graph (graph which gives the actual non linear variation of stress with strain) for analysis and design purposes. The purpose of the graph is: To find the area enclosed by the graph and then multiply the area with the width of the section (to get the volume of the stress

block), and this volume will give the magnitude of the force. To obtain the

graph, compression tests are done on concrete specimens at the lab,

and in these tests, the concrete is compressed to the ultimate state.

Based on these test readings, we can plot the graph which gives the

stress at various strains. Such a plot is given in fig.21 of the

code. In this fig., the top most curve shows the results (fck)

obtained from the tests conducted in the lab. But the

strength of concrete in an actual structure may not be as good as

that obtained in the lab. So only 67 percent of fck is taken. This is

shown in the middle curve. Then we have to apply the partial safety

factor for the material, which is concrete here. As seen before in

chapter 1, it's value is 1.5. So we get 0.67fck/1.5 =

0.447fck. Each of the y coordinate in the topmost curve is

multiplied by 0.447 to get the corresponding y coordinate of the

bottom most curve.

The 'effect' of reducing the value of fck to 0.447fck can be explained as follows: When we analyse a beam section by the limit state method, we are analysing it at the ultimate state. That is., we are trying to find the magnitude of the forces in the section when it is at the state of impending failure. According to the code, that state of impending failure is reached, if the stress in concrete is 0.447fck. We cannot take fck instead of 0.447fck. So the stress that concrete can be subjected to, is reduced from fck to 0.447fck. In effect, the contribution that can be expected from concrete is reduced.

The reduction from fck to 0.447fck has effect on design also. When we are designing a new section, we must expect the concrete to take a stress of only 0.447fck.

The maximum stress value of 0.447fck corresponds to the maximum strain of 0.0035. For the fibres with lower strains, the stress will also be lower. The bottom most curve in fig.21 is the curve in which the factor 0.447 has been applied to all it's points. So from that curve, we get the required stress for the fibres with lower strains also. Thus, it is the bottom most curve that we must use in analysis and design.

The 'effect' of reducing the value of fck to 0.447fck can be explained as follows: When we analyse a beam section by the limit state method, we are analysing it at the ultimate state. That is., we are trying to find the magnitude of the forces in the section when it is at the state of impending failure. According to the code, that state of impending failure is reached, if the stress in concrete is 0.447fck. We cannot take fck instead of 0.447fck. So the stress that concrete can be subjected to, is reduced from fck to 0.447fck. In effect, the contribution that can be expected from concrete is reduced.

The reduction from fck to 0.447fck has effect on design also. When we are designing a new section, we must expect the concrete to take a stress of only 0.447fck.

The maximum stress value of 0.447fck corresponds to the maximum strain of 0.0035. For the fibres with lower strains, the stress will also be lower. The bottom most curve in fig.21 is the curve in which the factor 0.447 has been applied to all it's points. So from that curve, we get the required stress for the fibres with lower strains also. Thus, it is the bottom most curve that we must use in analysis and design.

So,

in the Limit state method, we are considering sections at their point

of impending failure, and at this point, the stress distribution in

concrete is given by the graph in fig.21 of the code. And for

analysis and design purposes, we use the lower most graph in that

fig.

Let

us now examine the various features of this curve. We can see that

the curve has two portions. A parabolic portion, and a straight line

portion. The parabolic portion starts from the origin (0,0) where

stress = 0, and so strain is also equal to 0. From there, the stress

begins to increase with strain. This increase is parabolic. The

increase of stress continues upto the point where strain reaches

0.002. The maximum value of stress at this point is

0.447fck. When the strain

exceeds 0.002, the stress remains constant at 0.447fck.

The strain may continue to increase, but the stress will remain

constant. However, the strain cannot increase indefenitely. When it

reaches 0.0035, the code assumes that the concrete has

reached the point of impending failure. So after this point, the concrete will fail by crushing. In a beam section, the

topmost concrete fibres will be the ones that reach this strain

first. The lower fibres will be having lower strains. But as the

topmost fibres have reached the ultimate state, the whole section

should be considered to have reached the ultimate state. This is

because, the section will serve it's purpose only if strains in all

the fibres in it are below the specified limits.

In

a beam section which is subjected to a sagging moment, the Neutral axis

NA of the beam, corresponds to the origin point (0,0) in fig.21. This is because,

at the NA, both stress and strains are equal to zero. If this sagging moment is of such a magnitude that, the section is at the ultimate state, then, we can say that the stress variation in the section is given by the curve in fig.21 of the code. So, from the NA, as

we move up, the stress will vary parabolically upto the level where

strain equals 0.002, and then it will remain constant at 0.447fck.

At the top most level of the beam section, the strain is equal to

0.0035.

So

now we know that the bottom most curve is our required graph. We must plot it from the NA towards the upper part of the beam section. But we already know two important points on the graph. Origin point (0,0) at the NA, and the final point (0.447fck, 0.0035) at the top edge. So there is no need to plot it. We can take it and directly attach it to the beam section. We attach it in such a way

that the origin (0,0) is at the NA, and the strain 0.0035 is at the

top most level. Then we give the graph a thickness 'b' which is equal

to the width of the beam, and thus we get the 'Stress block'. This is

shown in the animation below:

So the final position of the concrete stress block in the beam will be as shown in the fig.3.1 below:

Fig.3.1

Concrete stress block in compression for a beam

In the above stress block, the only unknowns are the total depth of the stress block (depth of NA), and the depth of the rectangular portion. In our later discussions we will see the methods to calculate these depths.

There is also another point that we must note: We have attached the curve along the depth of the beam. The depth is a 'distance'. So it appears as if we plot the curve with 'stress' along one axis and 'distance' along the other axis. But the curve given by the code is a stress-strain curve. Not a stress-distance curve. Later in our discussions, we will see how they are related.

The graph of the stress block has a definite equation. We have seen it in chapter 1, and is given below again:

Eq.3.1

Concrete stress block in compression for a beam

In the above stress block, the only unknowns are the total depth of the stress block (depth of NA), and the depth of the rectangular portion. In our later discussions we will see the methods to calculate these depths.

There is also another point that we must note: We have attached the curve along the depth of the beam. The depth is a 'distance'. So it appears as if we plot the curve with 'stress' along one axis and 'distance' along the other axis. But the curve given by the code is a stress-strain curve. Not a stress-distance curve. Later in our discussions, we will see how they are related.

The graph of the stress block has a definite equation. We have seen it in chapter 1, and is given below again:

Eq.3.1

Where

fc is the stress and ε

is the strain

We

can make a plot of the design curve on our own, for any particular

value of fck

using Eq.3.1. For this we use the following steps:

• Choose

a value for the constant fck,

say

20 N/mm2

for M20 grade concrete.

• For

plotting the parabolic portion, choose values less than 0.002 for the

strain ε

(in

convenient steps of say 0.00025) and

for each of these values calculate the stress fc,

using the first part of Eq.3.1. The table 3.1 below shows the values of stress fc

when strain ε is

less than 0.002

Table 3.1:

Table 3.1:

| ε | fc |

| 0 | 0.000 |

| 0.00025 | 2.095 |

| 0.00050 | 3.911 |

| 0.00075 | 5.448 |

| 0.00100 | 6.705 |

| 0.00125 | 7.683 |

| 0.00150 | 8.381 |

| 0.00175 | 8.800 |

• For

plotting the straight line portion, we don’t have to choose values

for strain and calculate the corresponding stress. This is because it

is an equation of a horizontal straight line between strain (x) values ε

= 0.002 and 0.0035. The y values of all the points on that straight

line will be equal to 0.447 x 20 =8.94

. So

we can easily draw this second part.

• plot

ε

along the X axis and fc

along the Y axis

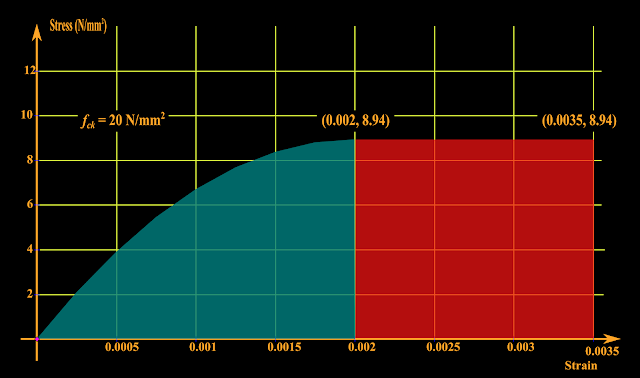

The coordinate points in the above graph are the same which are given in table 3.1. The area enclosed by the graph can be shown by shading the area between it and the X-axis. This is shown in the fig.3.3 below:

Fig.3.3

Area enclosed by the graph

In the next section we will discuss about the calculation of compressive force at a beam section by using this stress block.

PREVIOUS

NEXT

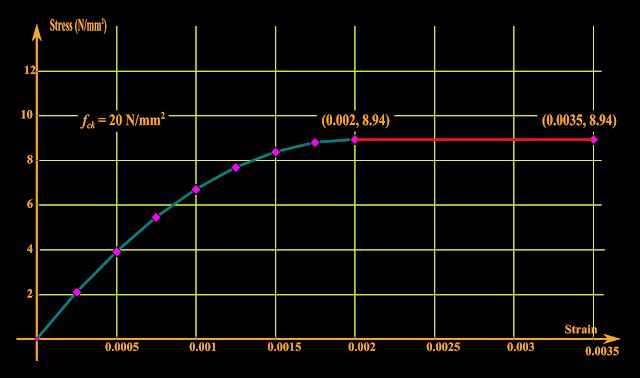

Fig.3.2 below shows the plot, where fck

=

20 N/mm2 . In

the plot, the parabolic portion is given blue colour and the straight

line portion is given a red colour.

Fig.3.2

Design curve for M20 grade concrete

Fig.3.2

Design curve for M20 grade concrete

The coordinate points in the above graph are the same which are given in table 3.1. The area enclosed by the graph can be shown by shading the area between it and the X-axis. This is shown in the fig.3.3 below:

Fig.3.3

Area enclosed by the graph

In the next section we will discuss about the calculation of compressive force at a beam section by using this stress block.

PREVIOUS

NEXT

Copyright ©2015 limitstatelessons.blogspot.com- All Rights Reserved

No comments:

Post a Comment